Modern Automated Semen Collection

At TSG we collect semen using the BoarMatic Collection System for superior comfort, safety and sanitation.

3rd Party Testing QA

Semen samples are regularly retained and sent twice per month to Kuster Research & Consulting for verification of TSG testing results. This ensures proper calibration of TSG equipment and provides a check and balance on internal testing procedures.

Verified Quality Semen

Pools are evaluated 6 times for motility and morphology.

The process from collection in our barn to delivery at your farm includes a series of verification steps for our product.

- 1. Collection temperature is recorded.

- 2. Extender is added .

- 3. Collection is analyzed for motility, morphology and concentration of sperm cells. Substandard collections are discarded.

- 4. The collection is fully extended and pooled with other collections. The full batch is evaluated again. At each step a failed evaluation means product is discarded.

- 5. The product is packaged and samples from each batch are retained for further testing.

- 6. The day after production, retained samples are retested.

- 7. 4 days after production, retained samples are retested.

- 8. 7 days after production, retained samples are retested.

- 9. 10 days after production, retained samples are retested.

Additional quality measures include:

4,300 semen samples per year are plated for bacteria monitoring

7,000 semen samples per year are stained for detailed morphology

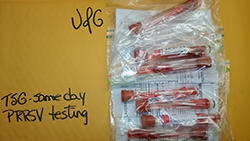

Twice weekly blood submission to U of G Animal Health Lab to screen for PRRS ~ 6800 bleedings annually

Advanced Laboratory

TSG laboratory staff are well trained and very experienced.

Data is managed using PRISM – a computerized system designed for managing boars, collections and semen testing results

Specialized equipment provides superior quality assurance adhering to IVOSII Semen QA protocols.

Superior Animal Health

Air Conditioning

We know that boars respond well to constant temperatures. Both animal health and fertility are improved with our climate controlled system. Our system provides cooling in summer months and heating in winter, with exhausted moisture being vented outside the barns. Ammonia requires moisture to become airborne, venting the moisture outside greatly improves air quality inside.

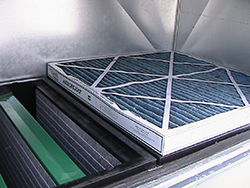

Air Filtration

To stop pathogens, TSG facilities have state of the art, fully filtered air, 100% of the time. Hospital operating rooms use air filters similar to ours.

3 Tier PRRS Prevention

At TSG we provide peace of mind to our semen customers through a three tiered approach to biosecurity.

- Prevention: Our facilities have complete air filtration using a MERV 3000 air filter. All air intake is 100% filtered. An air lock chamber has been added to allow fumigation and safe entry of large supplies.

- Monitoring: PRRS appears in the blood first. We take blood samples from our boars twice per week. U of G Animal Health Lab provides same-day results to TSG. Protocols are in place for the lab to immediately re-test any positive sample and to contact TSG immediately.

- Failsafe: Next morning delivery of semen provides a time delay during which test results can be verified and communicated to customers, should a positive test occur.

Bio-Security for Delivery

Protecting our customer is our priority. Our drivers are well trained and retrained annually in bio-security protocols.

Delivery drivers at the TSG facility use a separate drive way, separate entrance to the building, separate storage and loading room. This room is cleaned and disinfected after every delivery day.

Each customer delivery location and procedure is designed to meet strict rules to protect your farm as well as your fellow farmers.

New Boar Entry Protocol

All boars entering our stud are subjected to a stringent pre-entry health screening (blood testing), are quarantined for a period of time and extensively blood tested a second time to ensure the safest possible semen source for our customers. View protocol document.